Keylab

BayBatt Cell Technology Center

We need your consent to load content.

In order to show videos we use the services of third-party providers. These providers can collect data about your activities. Further details can be found under “Learn more”.Creators: Dylan Johannson (director), Jean Maurice Ehler (camera) and Nikolay Pershin (editor).

The University of Bayreuth's new Keylab BayBatt Cell Technology Center is a pivotal resource for battery researchers. It fosters collaboration and accelerates innovation by providing standardized production and evaluation of experimental cells. This ensures consistent results across research groups. The Keylab's comprehensive battery cell production capabilities establish it as a premier platform for advanced research and development, particularly in the field of pouch cell technology. Within a controlled glovebox environment designed to safely handle active materials (including lithium metal), it offers integrated synthesis, cell assembly, test, and post-mortem analysis capabilities.

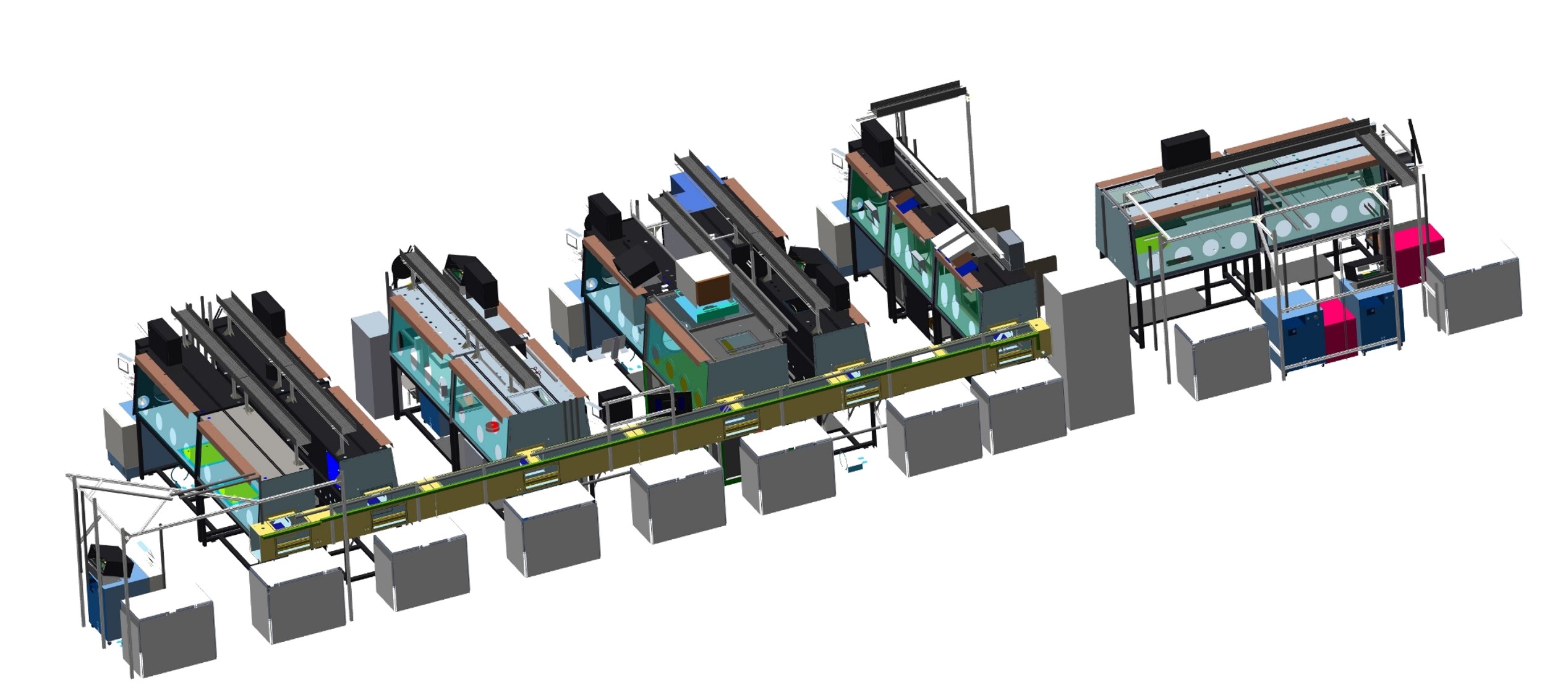

Drawing of the glovebox cluster, including its inert gas transport tunnel for transport.

Module Synthesis: Our equipment, including balances and dispersing units, accommodates batch sizes from several mL to 2 L, offering flexibility for your project needs.

Module Wet Coating: Our versatile coating capabilities ensure precision and scalability. The slot die coater offers highly reproducible results with controlled thickness variation (+/- 3%) and includes a heatable substrate holder (up to 200°C). Minimized material waste is ensured with a low dead volume (~2.5 mL). For diverse needs, a doctor blade coater and a heatable calendering unit (up to 200°C) are also available. Post-coating, active materials can be heated under vacuum (up to 400°C) within the glovebox. Lastly, our UV-ozone cleaner guarantees consistent substrate preparation.

Module Pouch Assembly: Our advanced assembly equipment provides lab-scale flexibility with industrial-level precision. Electrodes and separators can be precisely punched, and cell stacks are produced via single-sheet stacking. Our high-end automated solution combines adaptability with exceptional accuracy. Welding, lamination, and cup forming capabilities are integrated, along with automated electrolyte filling (2 to 250 mL) for state-of-the-art cell formats (40 x 60 mm & 80 x 120 mm).

Module Test & Cycling: Our high-precision test channels support impedance spectroscopy, formation, and cycling studies.

Module Physical Vapor Deposition: Our dedicated glovebox houses both thermal (lithium) and sputter (e.g., LIPON) deposition capabilities.

Module Analysis: Our advanced analysis capabilities ensure in-depth material understanding. A benchtop SEM (with BS-, SE-, and EDX-detectors) allows for detailed post-mortem analysis within the argon-controlled atmosphere (resolution < 100 nm), protecting sample integrity. Rheology studies (oscillation and rotation with Peltier-controlled temperature) enable slurry optimization, while Karl Fischer titration provides rigorous moisture content quantification.

Thermal Processing: Our integrated climate chamber and temperature-controlled antechambers ensure precise thermal processing conditions.

Gas Purification: State-of-the-art gas purification maintains nitrogen, oxygen, and water vapor levels below 1 ppm, allowing safe handling of sensitive materials, including acetonitrile.

Transportation System: Our inert transport tunnel (up to 1.5 kg load) enables contamination-free movement of samples between gloveboxes.