PhD projects

The following PhD projects are currently conducted at BayBatt chairs:

Physics

Doctoral students of the Chair of Theoretical Physics VII - Computational Materials Design:

- Thomas Bergler

- Tavinder Singh

- Franz Winkler

- Yao Yuxuan

Chemistry

- Correlated ion and electron transport in Li-ion battery cathode materials (Anna Asmedianova)Hide

-

In project “Correlated ion and electron transport in Li-ion battery cathode materials” we investigate the correlations between the movement of electrons and ions in cathode active materials for Li-ion batteries. The aim is to set up a combined experimental and computational approach, in collaboration with the chair of Theoretical Physics VII (Prof. Harald Oberhofer). In particular, after the synthesis of LiMnPO4 material, we will clarify the influence of defects (point defects, interfaces and grain boundaries) on carrier movements, and we will explicitly verify the influence of different levels of confinement (through channels’ dimensionality and finite sized grains) on the linked electron and ion movements. Finally, we will design materials with composition and morphology aiming at optimized transport properties.

The PhD project is being conducted at the Chair of Inorganic Active Materials for Electrochemical Energy Storage.

It is part of CRC 1585: Structured functional materials for multiple transport in nanoscale confinements (MultiTrans). - 4SBATT - Sustainable Solid-State Sodium Batteries (Hao Guo)Hide

-

My work will focus on the synthesis and characterisation of novel Na+ conductors with high ionic conductivity and thermodynamic stability.

The PhD project will be conducted as part of the 4SBATT project at the Chair of Inorganic Active Materials for Electrochemical Energy Storage.

- Polymer Cubosomes: Synthesis, Self-assembly and Conversion to Novel Anode Materials (Marvin Foith)Hide

-

Block copolymers can undergo self-assembly to form a new class of microparticles termed polymer Cubosomes. Polymer cubosomes consist of a periodic channel system, they are open porous, and have a high loading capacity. I will use polymer cubosomes either as template for metal oxides and transition metals or convert them directly to mesoporous carbon. The resulting materials will be then tested as novel anode materials for Lithium-ion batteries.

The PhD project is being conducted at the Chair of Polymer materials for electrochemical storage.

- Structured Polymer Solid Electrolytes and Composites for High Performance Lithium Metal Batteries (LMBs) (Amitha James)Hide

-

Lithium-based batteries are widely regarded as the preferred choice for electrochemical energy storage. Enhancing their cost-effectiveness and performance has the potential to significantly broaden their range of applications and facilitate the development of new technologies that rely on energy storage. Solid polymer electrolytes have garnered significant interest in high-performance LMBs due to their leak-proof properties, low flammability, excellent processability, flexibility, wide electrochemical stability range, exceptional safety, and superior thermal stability. My doctoral project deals with designing new solid polymer electrolytes, fabricating the cells and performing electro and physicochemical analysis to generate better understanding for the ion transport mechanism and the reaction processes.

The PhD project is being conducted at the Chair of Polymer materials for electrochemical storage.

- Heat transport and heat management in batteries: From the cell to the module (Flora Lebeda)Hide

-

In my dissertation, I am investigating thermal problems in batteries at the microstructure level. We are particularly interested in how heat transport can be designed by using intrinsic thermally anisotropic materials. Graphite, as one of the most commonly used anode materials, is an example of such a material. The targeted alignment of graphite particles can improve heat dissipation in the battery. In addition, hot spots can be avoided, which in turn reduces the degradation of the active battery material.

I also work with laser-based methods and IR thermography for the non-destructive evaluation of battery materials and battery cells. The next step is to extend our setup to extract the thermal properties of calendered electrodes. Together with detailed information about the microstructure, we can then specifically modify the heat transport in the electrode.The PhD project is being conducted at the Chair of Physical Chemistry I.

- Synthesis and characterization of disordered rock salt cathode materials for Li-ion batteries (Agnese Reitano)Hide

-

The aim of the study is to synthesise and characterise cathode materials with a Li-rich disordered rock salt structure, in order to improve the electrochemical performance of currently commercial cathode materials and to overcome some of the drawbacks that typically affect these materials. The samples will be studied using a combination of techniques including X-ray and neutron powder diffraction, in situ X-ray diffraction, and scanning electron microscopy to evaluate the crystal structure. Electrochemical tests and operando X-ray diffraction studies are also carried out in our laboratory to evaluate the performance and the crystallographic changes in real time.

The PhD project is being conducted at the Chair of Inorganic Active Materials for Electrochemical Energy Storage.

- Synthesis and Characterizations of Sodium Layered Oxides as Positive Electrode Materials for Sodium Ion Batteries (Mingfeng Xu)Hide

-

P2-type layered oxides exhibit superior Na ion conductivity and structural stability compared to their O3 analogues, making them promising candidate materials for the next generation batteries. However, the lower initial Na contents (Na/transition metals < 1) restrict their capacity during the first charge process, and the transitions between P- and O2-type structures during cycling further deteriorate their stability.

This work aims to increase the Na inventory in pristine cathode compositions, particularly relevant for full cell systems, while maintaining their cycling stability. The well-studied P2 material Na2/3Ni1/3Mn2/3O2 has been used as a starting reference material. Inactive element doping (e.g., Li incorporation) in the transition metal layers has been applied to stabilize the structure, while at the same time increasing the Na content.

In addition to fundamental structural and electrochemical characterization techniques, we also utilize advanced methods such as temperature-resolved in situ XRD in-house and operando XANES at synchrotron facilities. These techniques support the project in its ultimate quest of a high-capacity layered oxide with excellent cycling stability as a cathode material for sodium ion batteries.The PhD project is being conducted at the Chair of Inorganic Active Materials for Electrochemical Energy Storage.

Further doctoral students in Chemistry:

- Hafssa Arraghraghi (Chair of Inorganic Active Materials for Electrochemical Energy Storage)

- Nashmiya Basheer (Chair of Inorganic Colloid Chemistry for Electrochemical Energy Storage)

- Shweta Hiwase (Chair of Macromolecular Chemistry II)

- Rajneesh Kumar (Chair of Inorganic Colloid Chemistry for Electrochemical Energy Storage)

- Sandra Pappler (Chair of Inorganic Chemistry III)

- Dillon Max Stevenson (Chair of Inorganic Colloid Chemistry for Electrochemical Energy Storage)

- Gleb Zheleznov (Chair of Inorganic Active Materials for Electrochemical Energy Storage)

Engineering

- Digitalisation of Battery Testing (Hossein Harimi)Hide

-

The PhD project is being conducted at the Junior Professorship of Battery Management Methods.

- Characterisation of silicon-containing anode materials for lithium-ion batteries (Tilo Held)Hide

-

The project aims to improve the characterisation of silicon-containing anode materials for lithium-ion batteries through a holistic approach. By synthesising new composite materials, particularly Si-rGO composites, the performance and stability of the batteries will be optimised This will be achieved through the implementation of layered electrodes, which will then be electrochemically characterised using cycling, CV, differential capacitance analysis and impedance spectroscopy. In addition, physicochemical characterisation techniques such as SEM, TEM, FTIR, Raman, XRD, XPS and elemental analysis are used to gain a comprehensive insight into the structure and composition of the materials. The combination of these areas will provide insights into the de- and lithiation and degradation processes of the synthesised materials and electrodes, which will contribute to the further development of more powerful lithium-ion batteries.

The PhD project is being conducted at the Chair of Electrochemical Process Engineering.

- Detection of degradation mechanisms and fast-charging control of lithium-ion batteries (Andrea Kinberger)Hide

-

The conflict between high charging rates and battery lifetime is still a challenge in the development of electric vehicles and power-tools. It is necessary to identify operating conditions that trigger degradation processes to be able to combine fast charging with a long battery lifetime. Therefore, non-invasive sensing techniques that monitor real-time dynamics within the battery are crucial. With Operando EIS or dynamic electrochemical impedance spectroscopy (DEIS), impedance data is recorded under charge or discharge to gain information about the battery under operation. By examining impedance anomalies, evidence of battery damage can be found during operation. This method should be used to develop a fast-charging control of lithium-ion batteries based on impedance signals.

The PhD project is being conducted at the Chair of Electrical Energy Systems.

- Tailoring polymer-based electrolytes for solid and quasi-solid state Sodium batteries (Ho Mei Law)Hide

-

Our project involves the design and development of advanced polymer-based solid/quasi-solid electrolyte materials for Sodium based batteries through a comprehensive approach involving materials design and characterisation, and electrochemical investigations.

The PhD project is being conducted at the Chair of Electrode Design for Electrochemical Energy Systems.

- Sustainable material flows for lithium-ion and post-lithium batteries (Babatunde Omojola)Hide

-

The PhD project is being conducted at the Chair of Ecological Resource Technology.

- Glass separators for lithium-ion batteries (Philipp Rank)Hide

-

In case of overheating due to overcharging or a mechanical defect of lithium-ion batteries there is a safety risk due to the thermally unstable electrolyte. Contact with atmospheric oxygen or humidity leads to oxidation of the electrolyte and thus to heat generation, which starts a chain reaction known as thermal runaway. The battery separator as a passive, safety-relevant component in LIBs ensures the spatial separation of anode and cathode and thus prevents internal short circuits. As a temperature-stable alternative to state-of-the-art polymer separators, glass is to be used as separator material. High thermal and chemical resistance as well as good wettability with the battery electrolyte predestine glass for this application.

At Keylab Glass Technology, separators based on glass fibers and glass particles are produced and characterized using colloidal processes. In extensive electrochemical testing procedure, the performance and stability of the glass separators was proven in test cells. However, the higher density of glass reduces the gravimetric energy density of the battery cell, so that the focus of the current research is on reducing the thickness of the separator.The PhD project is being conducted at the KeyLab Glass Technology.

- Characterization and diagnosis of lithium-ion battery modules (Tom Rüther)Hide

-

The aim of the project is to identify and analyze the effects of different variations between individual cells within battery modules. To this end, novel characterization methods are developed and diagnostic procedures for the detection of inhomogeneities in battery modules are derived.

The PhD project is being conducted at the Chair of Electrical Energy Systems.

- Characterization, modeling and design optimization of battery electrodes (Maximilian Schamel)Hide

-

The main focus is on developing and applying models for battery electrodes, including porous electrodes for conventional lithium-ion batteries and composite electrodes for solid-state batteries. This work on solid-state batteries is being carried out in collaboration with colleagues from the Department of Functional Materials as part of the BMBF project FB2-AdBatt. The experimental characterization of electrodes is also a key aspect to parameterize the models. The ultimate goal is to facilitate model-based optimization of the electrode design for various target variables, such as energy density, rate capability, and homogeneity of electrode utilization.

The PhD project is being conducted at the Chair of Electrical Energy Systems. It is part of the BMBF competence cluster for solid-state batteries (FestBatt).

- Powder Aerosol Deposition of NaSICON-Type Solid Electrolytes for Sodium-Solid-State Batteries (Mutlucan Sozak)Hide

-

This research project investigates the feasibility of using Powder Aerosol Deposition (PAD) to fabricate micrometer-thin, dense, and ion-conductive NaSICON (Sodium Super Ionic Conductor) membranes for next-generation sodium-based solid-state batteries (SSSBs). These batteries offer several advantages over traditional lithium-ion batteries, including the use of more abundant and environmentally friendly sodium and the potential for higher energy densities and improved safety due to the solid electrolyte. The project focuses on the optimization of process conditions and parameters for PAD-NaSICON membranes, rather than material development.

The project focuses on three key aspects: achieving dense, sodium-conducting NaSICON membranes using PAD, understanding the relationship between the resulting microstructure and achievable room-temperature ionic conductivity, and exploring the potential of moderate annealing to enhance conductivity and reduce interface resistance. Additionally, researchers aim to demonstrate the feasibility of constructing sodium-conducting cells entirely with PAD-fabricated functional layers. The ultimate goal is to assemble an all-solid-state sodium battery by sequentially depositing cathode and solid electrolyte layers via PAD and to utilize Na metal as anode.The PhD project is being conducted at the Chair of Functional Materials.

- Model-based investigation of formation process and its influence on the ageing behaviour of lithium-ion batteries (Felix Schomburg)Hide

-

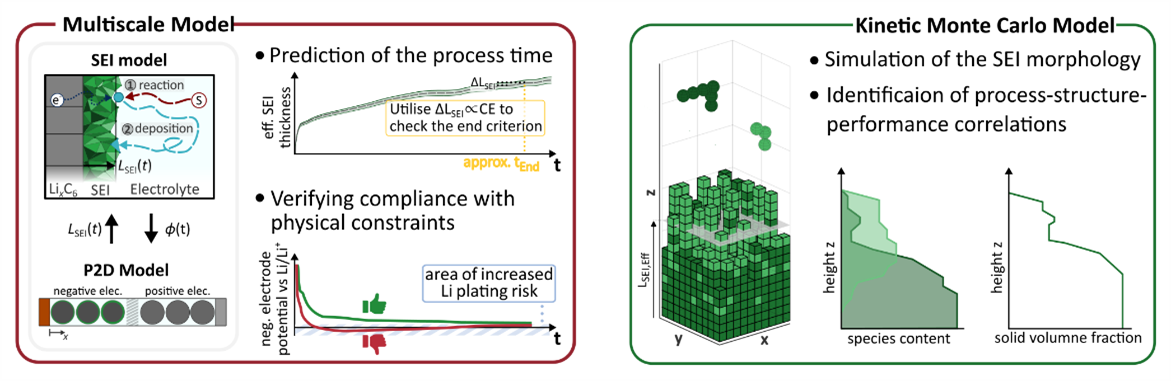

The formation process is a complex, yet crucial step in the lithium-ion battery (LIB) manufactoring as it significantly impacts the LIBs performance and cost. The aim of the research project is to develop methods that enable a material-dependent design of the formation protocol. To this end, electrochemical and simulative methods are developed and deployed to improve process understanding. The focus is on multi-scale simulations, which combine electrochemical cell models with continuous SEI growth models, and atomstic Kinetic Monte Carlo models to extrapolate and analyse the impact of the formation, respectively. The concluding aim is to combine the experimental and simulative methods into a framework to enable an efficient methodology for multi-critical design of formation protocols.

The PhD project is being conducted at the Junior Professorship of Battery Management Methods.

Further doctoral students in the Engineering Sciences:

- Lukas Hennerici (Chair of Functional Materials)

- Leonard Jahn (Chair of Electrical Energy Systems)

- Tobias Michlik (Chair of Materials Process Engineering)

- Patrick Mößle (Chair of Electrical Energy Systems)

- Gregor Ohnemüller (Chair of Environmentally Sound Production Engineering)

- Christian Plank (Chair of Electrical Energy Systems)

- Srivatsan Ramasubramanian (Junior Professorship for Battery Management Methods)

- Venkata Sai Subhash Ganti (Junior Professorship for Computational Materials Science)